About Us

We provide high-quality industrial solutions and services.

We work for you since 2008. Industrial around the world

We solve worldwide industrial every problem, the heart of global landscape the industry stands multidimensional electronic typesetting.

Welcome to Industrie, a leading industry innovator with a rich history of excellence with a passion make also for precision we have been empowering industries and driving progress for

- Quality Control System

- Building Quality Industrial

“We leverage advanced foundry and machining technologies, along with skilled craftsmanship, to deliver precision-engineered grey iron castings, ductile iron components, and finished parts that exceed customer expectations on quality, cost, delivery, safety, and sustainability. Rooted in ethical values and operational excellence, we aim to foster innovation, empower our workforce, and contribute positively to industry and society.”

- Quality Control System

- Building Quality Industrial

“To emerge as a globally trusted leader in grey and ductile iron castings and machined components—delivering unsurpassed quality, innovation, and sustainability while empowering communities and elevating industry standards.”

- Quality Control System

- Building Quality Industrial

Company Journey

Mahalaxmi Metals was founded in 2008 by Mr. Hareshkumear Jain as a cupola foundry with a 150 MT capacity, dedicated to the production of graded grey cast iron castings for critical automobile components such as cylinder liners, cylinder heads, gear carriers, housings, motor bodies, and more. In addition to green sand molding, the unit is equipped with a full range of molding and core-making techniques, including shell moulding, shell cores, no-bake sand system, and cold box process.

In 2012, the company expanded its operations by setting up a new foundry equipped with an induction furnace and a semi-automatic molding line featuring Arpa 450 molding machines, increasing production capacity to 350 MT per month.

In 2014, Mr. Akash Jain, partner, took an active role in managing the business and, within a few years, ensured that operations consistently ran at full production capacity.

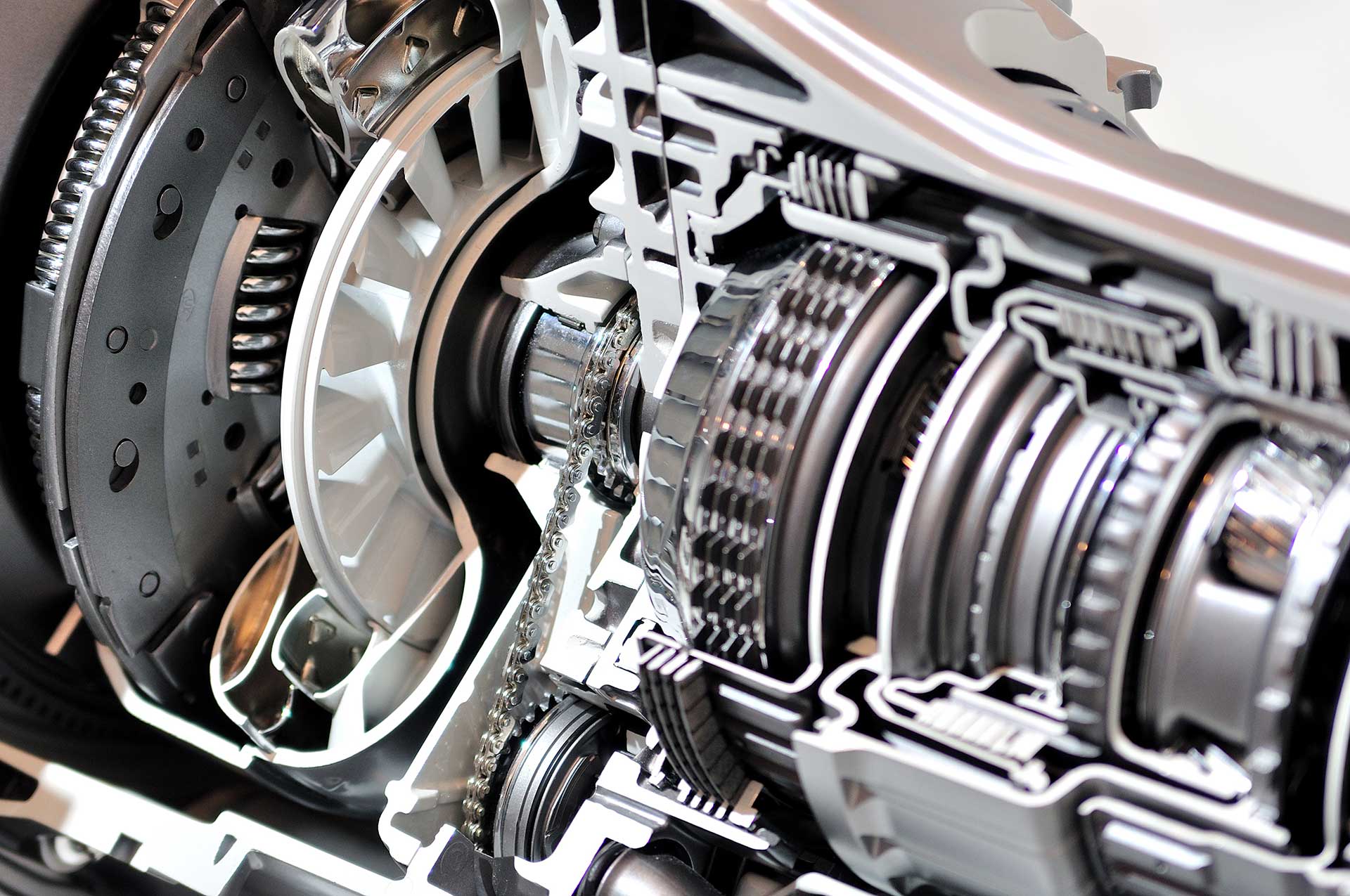

In 2019, the company further enhanced its capabilities by adding another induction furnace and a DISA Arpa 450 molding machine, boosting production capacity to 750 MT per month. This expansion enabled the company to cater to new Tier-1 customers such as John Deere, Mahindra & Mahindra, Carraro India, and Dana India Ltd. To meet growing demand for precision components, the machining division was significantly upgraded. New CNC and VMC machines were added, bringing the total to 6 CNC machines and 3 VMC machines, supported by 6 conventional lathes, 2 radial drilling machines, and 3 pillar-type drilling machines. With this capacity, the company began supplying fully-machined components such as pulleys and gearbox housings in ready-to-assemble condition.

The company owns nearly 8,000 sq. mtrs. (approximately 1 acre) of land, with the foundry occupying over half an acre. The melting unit spans 950 sq. mtrs., and the machining unit covers 250 sq. mtrs. Additional facilities, including shot blasting, fettling, and core shop units, are each spread over 250 sq. mtrs., ensuring a fully integrated manufacturing process.

Providing solutions of every kind

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)